Y2 Series Motor Stator Laminations: Selection Guide and Key Features

Efficient and reliable electric motors are essential across a broad range of industrial and commercial applications, from pumps, compressors, and conveyors to HVAC systems and VFD-driven machinery. The performance and durability of these motors largely depend on the stator core, where laminated steel sheets form the foundation of the magnetic circuit. The Y2 Series Motor Stator Laminations are designed to optimize energy efficiency, reduce losses, and enhance mechanical stability, providing manufacturers and OEMs with a reliable solution for consistent motor performance.

Global industrial growth and stricter energy efficiency regulations have intensified the focus on motor performance. Stator laminations account for a significant portion of core losses in motors, which can translate into higher energy consumption, increased operating costs, and shorter service life. The adoption of variable frequency drives (VFDs) and high-speed motor applications has further emphasized the need for laminations with precise magnetic and mechanical properties. Y2 Series laminations address these challenges, ensuring reduced core losses, minimized vibration, and long-term operational reliability.

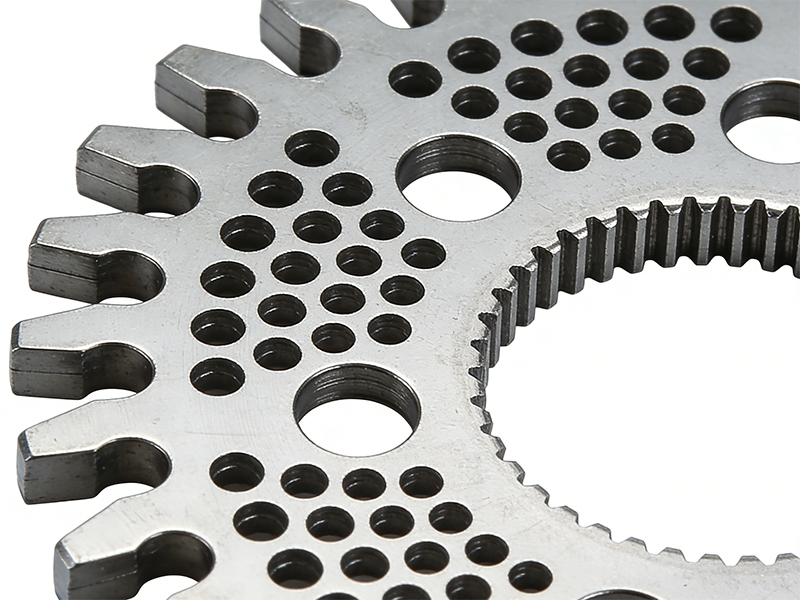

Motor stator laminations are thin sheets of electrical steel stacked to form the stator core. Their primary function is to provide a low-loss magnetic path while limiting eddy currents and hysteresis losses. The Y2 Series laminations are engineered for uniform magnetic flux distribution, which minimizes torque ripple, reduces vibration, and enhances overall motor efficiency. The precision in lamination design, including accurate slot shapes and thickness tolerances, ensures optimal electromagnetic performance while supporting the mechanical integrity of the motor under operational stresses.

Y2 Series stator laminations are manufactured from high-quality silicon electrical steel with a controlled thickness, typically ranging from 0.20 to 0.35 mm. The steel is coated with insulating layers that prevent interlaminar eddy currents and improve mechanical damping, reducing noise and vibration. Advanced stamping or laser cutting techniques ensure dimensional accuracy and clean edges, minimizing burrs that could interfere with assembly or electrical performance. Laminations are then stacked using interlocking, adhesive, or mechanical compression methods to maintain uniform alignment and rigidity. Stress-relief annealing further enhances magnetic properties and reduces internal mechanical stresses.

Several critical factors influence the effectiveness of Y2 Series laminations:

Material quality: High-grade electrical steel ensures consistent magnetic properties and minimal core loss.

Lamination thickness and tolerances: Uniform thickness reduces eddy currents while maintaining structural stability.

Insulation integrity: High-quality coatings prevent interlaminar shorts and support vibration damping.

Stacking precision: Proper alignment prevents hotspots, uneven flux distribution, and mechanical resonance that could reduce efficiency.

Selecting a reliable supplier for Y2 Series laminations is essential for ensuring quality and consistency. Important criteria include:

Traceable steel grades and insulation certifications.

Precision manufacturing capabilities for stamping, cutting, and stacking.

Comprehensive quality control for magnetic properties, core loss, and mechanical tolerances.

Engineering support for custom designs and stack optimization based on motor specifications.

Reliable suppliers provide consistent batches and technical guidance, helping manufacturers meet efficiency standards and reduce rework or downtime.

Even with high-quality laminations, motor manufacturers face challenges such as:

Variability in steel properties across production batches, affecting magnetic performance.

Mechanical misalignment or improper stacking leading to vibration and noise.

Thermal stress in high-load or continuous-duty applications impacting insulation or stack integrity.

Balancing lamination thickness for optimal magnetic performance while ensuring mechanical robustness.

Addressing these challenges requires rigorous quality control, precise assembly, and thorough testing under realistic operational conditions.

Y2 Series laminations are suitable for a wide range of motor types and industrial applications:

HVAC motors: Enhancing energy efficiency and reducing operational noise.

Industrial pumps and compressors: Maintaining performance under continuous duty cycles.

Conveyors and material handling systems: Reducing vibration and mechanical wear for long-term reliability.

VFD-driven equipment: Supporting variable-speed operation with stable torque and minimal losses.

In all scenarios, Y2 Series laminations contribute to reliable, efficient, and durable motor performance, lowering operational costs and extending service life.

The future of stator lamination design focuses on advanced materials, thinner laminations, and improved insulation technologies. Digital modeling and finite element analysis allow manufacturers to simulate core losses, flux distribution, and thermal behavior before production, optimizing performance and efficiency. There is also increasing interest in eco-friendly steel materials and energy-efficient motor designs, aligning with global sustainability goals. As industrial electrification and automation continue to grow, Y2 Series laminations will remain a critical component for achieving high-performance, cost-effective, and reliable motors.

Q: What are the main benefits of Y2 Series laminations?

They provide reduced core losses, enhanced magnetic flux distribution, minimized vibration, and long-term mechanical stability.

Q: How does lamination thickness affect motor performance?

Thinner laminations reduce eddy current losses, while precise tolerances ensure mechanical stability and uniform magnetic properties.

Q: Can Y2 Series laminations improve VFD motor efficiency?

Yes, the uniform magnetic path and low-loss material enhance efficiency and ensure consistent performance under variable-speed operation.

By combining high-quality materials, precision manufacturing, and optimized design, Y2 Series Motor Stator Laminations deliver durable, energy-efficient, and reliable solutions for industrial motor manufacturing.

Bản quyền © Công ty TNHH Công nghệ Cơ điện Chiết Giang Xinzheng Mọi quyền được bảo lưu.

Trang web này sử dụng cookie để đảm bảo bạn có được trải nghiệm tốt nhất trên trang web của chúng tôi.

Bình luận

(0)