High‑Efficiency YVF2 Motor Laminations for Variable Frequency Drives: A Technical Overview

In modern industrial automation and energy systems, the drive toward greater energy efficiency and reliability is reshaping motor design. Driven by regulatory standards (e.g., IEC/EN efficiency classes) and rising electricity costs, electrical machine manufacturers increasingly specify optimized core components to reduce losses and improve performance. Variable frequency drives (VFDs) are central to this trend because they enable precise speed control and torque delivery in pumps, compressors, conveyors, and HVAC systems. However, VFD operation imposes electrical and thermal stresses on motors that directly influence long‑term durability and efficiency — a challenge that begins with core material and lamination design in the motor stator and rotor.

Global demand for high‑efficiency electric motors continues to grow across industrial, commercial, and infrastructure sectors. The adoption of VFD‑controlled systems is expanding as facilities seek to optimize processes while reducing energy consumption and maintenance overhead. As a result, core laminations designed for VFD compatibility have become an area of competitive differentiation for motor OEMs, particularly in markets requiring premium performance or extended duty cycles. Precise lamination stacks contribute substantially to lowering core losses — a major factor in total motor losses at variable frequencies — and help motors meet stringent efficiency targets while maintaining reliability over service life.

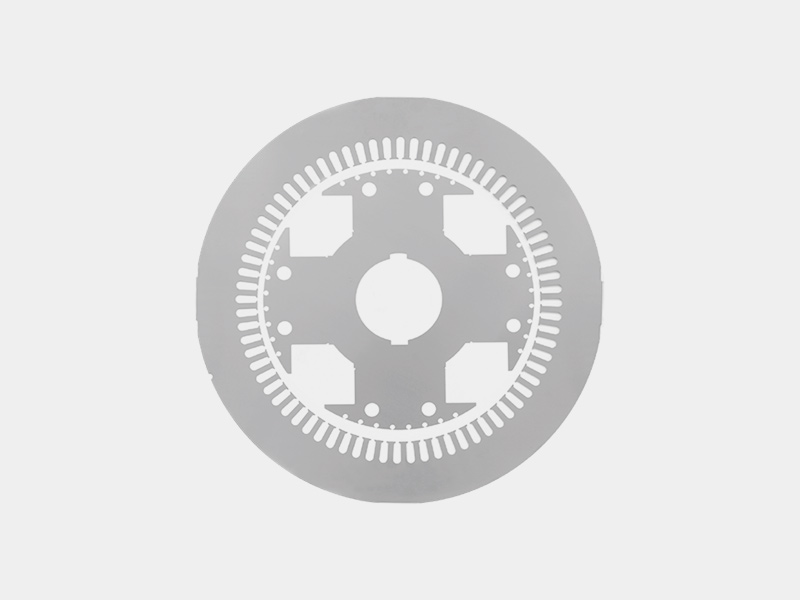

Motor laminations are thin steel sheets that form the electromagnetic core of an electric motor. Their primary function is to establish an efficient magnetic circuit and minimize eddy current and hysteresis losses that occur when alternating magnetic fields interact with conductive material. VFDs introduce a wide range of frequencies during acceleration, deceleration, and steady‑state operation, so the magnetic properties and thickness of lamination material must be selected to balance performance, loss reduction, and manufacturability.

YVF2‑class laminations typically consist of high‑grade silicon electrical steel, chosen for its ability to reduce eddy currents and improve magnetic permeability. Silicon content increases resistance, which limits circulating currents induced by changing magnetic flux, while maintaining structural integrity at high rotational speeds. The steel is produced in very thin gauges (often between 0.20–0.35 mm for VFD use) to further reduce core loss without compromising mechanical strength.

Manufacturing involves precision stamping or laser cutting of each lamination to tight tolerances, followed by insulated stacking. Insulation coatings between sheets prevent interlaminar eddy currents, while advanced stacking techniques (e.g., interlocking or welding) maintain geometric accuracy and mechanical stability. Annealing may follow fabrication to relieve internal stresses and optimize magnetic characteristics.

Several variables influence the final motor’s behavior under VFD control:

Material grade and silicon content: Higher silicon can reduce losses but may affect ductility and manufacturability if over‑optimized.

Lamination thickness: Thinner sheets reduce eddy current paths and core loss, especially at higher frequencies, but increase production complexity and cost.

Insulation and coatings: Quality insulation prevents interlaminar shorts and preserves magnetic efficiency; long‑term thermal stability of coatings is critical for heavy‑duty applications.

Stack assembly precision: Uniform stacking minimizes vibration, noise, and local hot spots, which are especially important for VFD‑induced harmonics.

Selecting a supplier for YVF2 motor laminations requires evaluation of manufacturing capability, material traceability, and quality control protocols. Key criteria include:

Capacity for tight dimensional tolerance and repeatability, especially for thin‑gauge steel.

Demonstrated expertise in insulation coatings and stress‑relief treatments.

Certifications aligning with industry standards for material quality and environmental compliance.

Engineering support for lamination design and stack optimization, which can influence motor performance for specific applications.

A robust supplier ecosystem ensures resilience and consistent delivery in high‑mix, low‑volume industrial markets where specification changes may arise.

Professionals working with VFD‑driven motors often encounter persistent issues related to core design:

Excessive heat and core loss at non‑rated frequencies, which can degrade performance if laminations are inadequately specified.

Noise and vibration linked to poor stacking precision or inadequate insulation integrity.

Material inconsistency leading to variation in efficiency and torque profiles across production batches.

Addressing these pain points requires both proper initial design and rigorous quality assurance in lamination production.

High‑efficiency YVF2 motor laminations are integral to a wide range of industrial applications:

Pumps and fans in HVAC systems, where variable speed control yields energy savings.

Centrifugal compressors and extruders in manufacturing, which demand precise torque performance.

Material handling and robotics, where responsiveness and reliability under frequent speed changes are essential.

High duty‑cycle conveyors and mining equipment, where core losses have significant operational cost impacts.

In each case, optimized lamination stacks contribute directly to lower energy consumption and enhanced system uptime.

Emerging trends in motor lamination technology focus on material innovation and digital manufacturing integration. Research into advanced soft magnetic alloys and nanocrystalline materials seeks to push performance beyond conventional silicon steel limits, particularly for high‑frequency and high‑power density motors. Meanwhile, digital design tools and simulation are enabling more accurate prediction of core losses and thermal behavior, improving first‑time design success rates.

Automation in stamping, inspection, and stack assembly is also extending capabilities for custom and small‑batch production, aligning with flexible manufacturing paradigms. As efficiency standards tighten and electrification continues to expand across sectors, the role of high‑efficiency laminations in motor design will only grow in strategic importance.

Q: Why are motor laminations essential for VFD applications?

Laminations reduce eddy current and hysteresis losses that become more pronounced under variable frequencies, maintaining efficiency and thermal stability in VFD‑driven motors.

Q: How does lamination thickness affect performance?

Thinner laminations limit the path for induced currents, reducing core losses at higher operating frequencies, but they require higher manufacturing precision.

Q: Can alternative materials improve lamination performance?

Yes — advanced alloys like soft magnetic composites or nanocrystalline materials show promise at very high frequencies, though cost and production complexity remain considerations.

This structured, engineering‑oriented overview highlights the integral role that high‑efficiency YVF2 motor laminations play in modern VFD systems, situating them within broader industry demands and technological evolution.

Bản quyền © Công ty TNHH Công nghệ Cơ điện Chiết Giang Xinzheng Mọi quyền được bảo lưu.

Trang web này sử dụng cookie để đảm bảo bạn có được trải nghiệm tốt nhất trên trang web của chúng tôi.

Bình luận

(0)